Paper cassette tape case

I designed and laser-cut a foldable case for cassette tapes.

You can download the SVG template here and customize it for your own use.

It's a standard US-letter sheet (8.5"x11") with 0.25" border on all sides.

Note: The red lines are score lines and should probably be removed prior to cutting. Alternatively, your laser cutter might be able to use these for lower-power etching/burning...if you try that, let me know how it goes!.

background

In the summer of 2020, I initiated a split cassette collaboration with my friend Sun Tunnel.

I did some research, ordered some tapes, and started working on the packaging. I had previously bought at least one other tape with a nice cardstock foldable case...so I heavily based the design here on that tape.

The company that I purchased the blank cassettes from also sells and prints a foldable design called the "maltese cross", which I like and is also very similar to this, but a full color print job was over budget and totally overkill for our project. We wanted to keep it cheap and largely DIY.

I did a search, but didn't find any similar templates online (note: if you find one, please let me know and I'll be sure to link it here). I then set out to make one myself in Inkscape. I couldn't easily find a template online, so that's why I'm offering it here)!

Once I had a basic design, I traced it onto cardstock and cut it, scored it, and folded it by hand to see how it looked/felt:

I was happy with the design, made some finishing tweaks, and tweaked it so that it would fit on a single US-letter (8.5" x 11") page.

Time to cut! I solicited laser cutting help from some friends, and ended up visiting my pal Cory's workshop. He has a laser cutter that he wanted to spend a bit more time with, and this low-impact pretty easy project was a pretty good match.

After some experimentation with number of sheets and pass-count (how many times the laser travels over the same area), we ended up with a sweet spot. I think we ended up stacking 4, and cutting 2 at a time with 100% power and 4 passes. Not sure why (I'm sure there are a number of factors), but the laser wasn't happy cutting more than just a couple of sheets. In any case, 30+ print jobs later, we had a nice stack that smelled of burned paper! It was awesome.

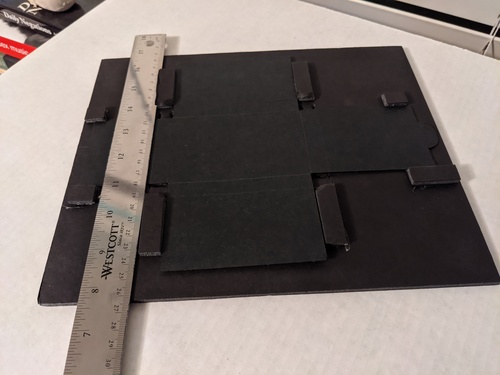

After the cutting was complete, I designed and built a little scoring jig to assist in folding. When working with cardstock, I think proper scoring is essential.

I made more than 500 score lines. The tape isn't done, but the couple of test folds turned out very well and I'm happy with the progress.

tweaks

There are a few tweaks I would make for next time:

- Increase the corner rounding. I liked the prototype rounding, and the actual version turned out less round. I'd try and expand it to somewhere in between.

- Try using a lower power for the laser to make the score lines. The scoring is a bit of effort, and this might eliminate that.

- Try using dashed/dotted lines for scoring? The laser doesn't cut a full line, but just dashes...hmm.

- Windowed cuts - to put paper inside or just to embellish and make fancy.