Building contact mics

Tue Feb 21 2023 22:29:13 GMT-0800 (Pacific Standard Time)

tags: noise audio piezo microphones

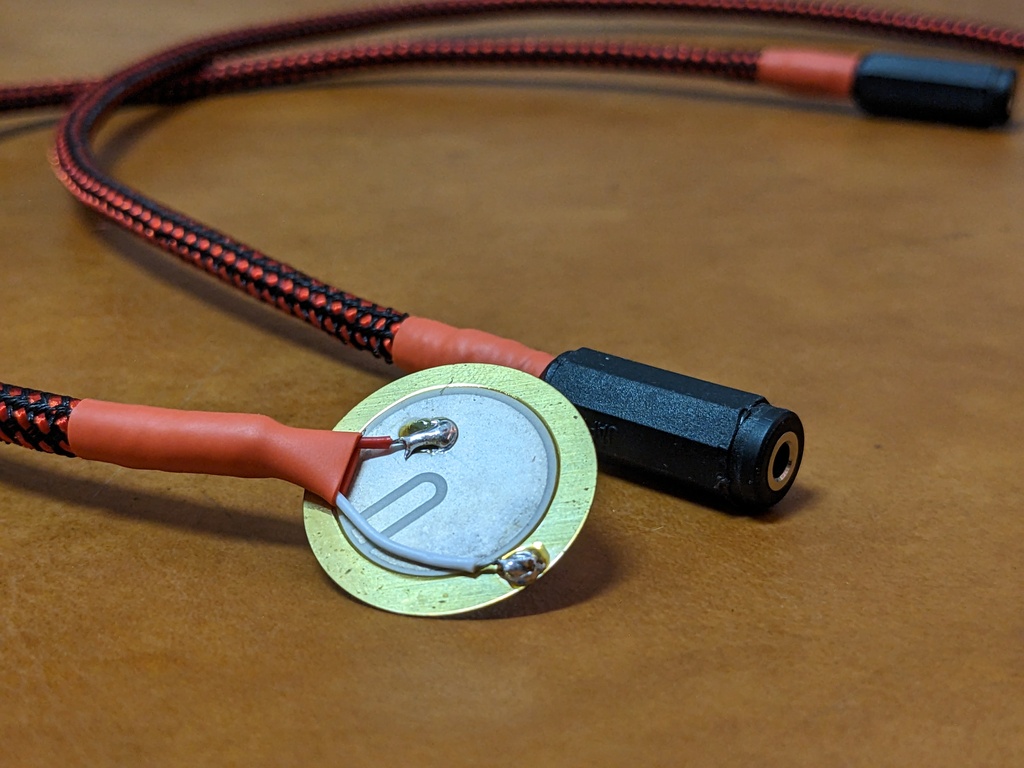

Finally starting a process of building a small collection of ACTUALLY USABLE diy contact microphones.

The ones pictured here will have some strain relief before being plasti-dipped.

I've built these over the years, but never of any decent quality. In fact, I think the one I made

back in 2005 when I made the

Liar's Rail recording just had some exposed

solid-conductor twisted pair wire hanging off it (recycled phone cord or ethernet I think).

So any time in the last couple of years that I've reached for one in the parts bin it seems to always be screwed up and doesn't work right. That frustration plus a small surplus of discs remaining from Wacky Willy's days provoked this process.

It's purely an aesthetic choice, but I now totally love cables with nylon sleeves over them now. This is my first time actually hacking/reusing some cable like that. I think maybe the right thing to do is to buy the sleeving separately, but I got lazy and hurried into buying a longer prefab cable for reuse. It's fine and totally workable, but some cable does get wasted due to fraying. If you look carefully in the photo above, one of the mics has a larger black piece of heat shrink covering some area where the sleeve didn't stretch as much as I had expected. I think it won't matter much once it's dipped, but there's a learning process here for me.

Tonight was also my first attempt at recording directly from the contact mics with the Zoom H2n. The default mic power was enabled, and the sound was very clear and loud. Stoked it worked so well.

I intend to also build some other formats, like:

- rigid epoxy puck

- dual vocal chord throat mic choker

- fidget spinner contact mic box

- hydrophone